ABOUT

DPFS and DOCS

DPFs

A diesel particulate filter, or DPF, is a device comprised of a wall-flow substrate typically made of porous ceramic media that captures exhaust gas and removes PM or soot particles. A typical filter consists of an array of small channels for exhaust gas to flow. Adjacent channels are plugged at opposite ends, forcing the exhaust gas to flow through the porous wall, capturing the soot particles on the surface and inside pores of the media. As soot accumulates in the filter, a regeneration event will provide sufficient heat to oxidize and capture the soot. The remaining ash can be removed during regularly scheduled cleaning events based on the recommendations of the engine manufacturer.

When maintaining your aftertreatment system you should weigh your options. While DPF cleaning is a cost-effective method for your first scheduled maintenance event, you can’t always be sure of what is left behind. Each cycle can deposit hardened ash that is not removed with cleaning which will negatively affect performance. Back pressure is increased, porosity is reduced and the effective cycle is shortened requiring more frequent maintenance.

Replacing your DPF with a new Durafit DPF pays benefits in improved fuel economy, fewer active regens, and better performance.

DOCs

Diesel oxidation catalyst (DOC) is a diesel engine after-treatment device, which consists of a ceramic/metal honeycomb substrate coated with high activity precious-metal-based oxidation catalyst, packaged in a stainless steel container. The diesel oxidation catalyst is designed to convert carbon monoxide (CO), hydrocarbons (HC), and the SOF fraction of particulate matter into carbon dioxide(CO2)and water (H2O).

Durafit Diesel Oxidation Catalyst (DOC) Features:

- Excellent oxidation performance;

- Low light-off temperature for HC, CO, and SOF;

- High conversion efficiency.

- Active catalyst ingredients: Proprietary Aristo catalytic coatings

- Cell density: 200 CPSI, 300CPSI,400CPSI.

Diesel Oxidation Catalyst (DOC) Function:

- Oxidize HC and CO in diesel exhausts gas emission.

- Oxidize the SOF of particulate matter (PM).

- Partially oxidize the SOOT of PM.

- As the first stage of the SCR catalyst, oxidize NO into NO2 to improve the conversion efficiency of NOx.

- Enables additional passive regeneration in DPF system.

Durafit Aftermarket DOC filters – Available for a wide variety of heavy-duty and medium-duty on-highway diesel applications including: heavy-duty trucks, medium-duty trucks, school buses, motor coaches, shuttle buses, and light-duty diesel pick-ups. Each Durafit DOC is designed as a direct replacement for the OEM filter. Our exact fit approach makes installation fast and easy without cutting or welding to get you back on the road. Durafit DOCs are designed and manufactured in the USA.

Durafit DOCs are new, never rebuilt, with no core required.

WHAT CAUSES A DOC TO FAIL?

Common Failures include

HC injector clogging

Fuel can mix with soot and clog the injector

EGR Coolant Leaks and turbo failures

Oil and /or coolant in the exhaust stream will contaminate the precious metal wash coating leading to reduced DOC function. This reduction in function will restrict the oxidation function keeping it from raising the temperature high enough for proper regeneration in the DPF.

FAQ's

Fuel and oil contain inorganic additives to help protect your engine and extend the life of the oil. During the combustion process, they are turned into ash, which collects in the diesel particulate filter over time. Unlike the black carbon and soot in the exhaust, which is reduced during the regeneration process, the ash can only be removed by a cleaning device. This requires the diesel particulate filter to be removed from the engine. The cleaning interval varies for each engine manufacturer (and sometimes between engines from the same manufacturer) and can be found in your vehicle’s service guidelines. You should follow the engine manufacturer’s recommended cleaning intervals for your Durafit diesel particulate filter just like you would for the original diesel particulate filter.

Note that the amount of ash is directly related to the amount of oil an engine consumes. High oil consumption or high hours of service means more ash in the diesel particulate filter and may require more frequent cleaning.

A network of diesel particulate filter cleaning services has developed since diesel particulate filters became standard equipment on trucks and buses. Some Durafit distributors also have cleaning services, so your Durafit distributor would be a good starting point to find a reliable cleaning service.

You can only if you use a filter cleaning machine that is approved by the OEM. (Despite what you see on YouTube; garden hoses, pressure washers, and other household cleaners are not recommended.)

No, unless diesel oxidation catalyst maintenance is specifically called out in your engine’s maintenance instructions.

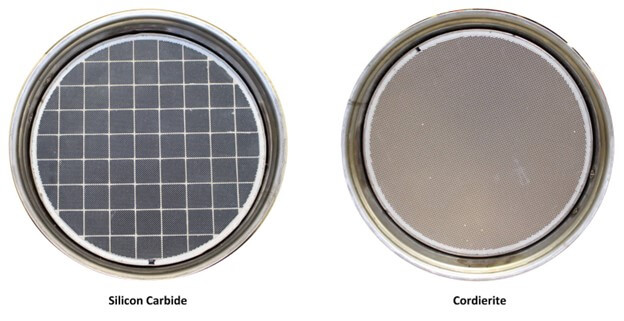

In recent years, some OEMs have started to use a different type of diesel particulate filter material in their heavy-duty aftertreatment systems. Since Durafit matches the OEM design, our diesel particulate filters use the same type of filter material.

These diesel particulate filters are made from a material called Silicon Carbide (sometimes abbreviated as SiC, its chemical formula). It differs from the more common material (cordierite) in color and how the filter is assembled. Silicon carbide is dark gray and the diesel particulate filter is almost always a collection of smaller pieces that are cemented together, often in a checkerboard pattern. In contrast, a cordierite diesel particulate filter is typically t

an and built as a single continuous cylinder. The photos below illustrate these differences.

Unless the OEM specifies otherwise in their service documents, a cordierite filter must always be replaced by a cordierite filter, and a silicon carbide filter replaced by a silicon carbide filter. Although both diesel particulate filter types provide nearly 100% PM reduction efficiency, the OEM’s regeneration strategy and fault codes are designed around a particular material, so switching materials without OEM authorization could cause undesirable effects.

A poorly maintained engine lowers your fuel economy, increases emissions, and shortens the life of your engine and emissions critical components such as the diesel particulate filter and diesel oxidation catalyst. Deferred or neglected maintenance items may include the following: restricted air filters, stuck EGR valves, faulty fuel injectors, faulty turbochargers, and degraded charge air coolers.

Regular vehicle, engine, and after-treatment maintenance, (including the diesel particulate filter), will yield more vehicle “uptime,” with reduced operating costs, and maximize your return on the investment that you made in the vehicle.

As an engine runs, the diesel particulate filter collects solid particles called particulate matter (“PM”) which consists of carbon, unburned fuel, and oil, the ash from fuel and oil additives, as well as any other contaminants from the exhaust. Over time, the diesel particulate filter will fill with PM. The process of removing the combustible part of the PM (the carbon, unburned fuel, and unburned oil) is called “regeneration.”

Under driving conditions with the engine producing high exhaust temperatures – on a highway or pulling a heavy load – the catalytic coatings on the diesel particulate filter and diesel oxidation catalyst are sufficient to keep the diesel particulate filter clean. This cleaning process that takes place without any activity by the engine is called “passive regeneration.”

When the exhaust temperature is not sufficiently high, the vehicle’s exhaust system relies on auxiliary fuel injection to raise the temperature of the diesel particulate filter to a level at which most of the PM is oxidized. This process is actively controlled by the engine‘s controller and is therefore called “active regeneration.” The active regeneration occurs periodically and is not noticeable to the driver. Numerous sensors on the engine and exhaust system provide input to the engine‘s controller so it can trigger and control the process.

Forced regeneration is an active regeneration that is initiated by the operator when the vehicle is standing still. During the process, the engine controller modifies the engine speed, intake air flow, EGR rate, and other functions to allow the diesel particulate filter temperature to reach a suitable temperature. Consult your engine or vehicle owner’s manual for details.

In most cases, your vehicle relies on both passive and active regeneration to keep the diesel particulate filter clean and the vehicle operating normally.

Extended periods of idling shorten the lifetime of your engine, consume fuel unnecessarily, and load up the DPF with particle material. This will generally trigger active regeneration events, consuming even more fuel and putting greater thermal stresses on your aftertreatment system.

In addition, some states, private entity properties, and many municipalities have strict anti-idling laws or policies.

Durafit diesel particulate filters and diesel oxidation catalysts are sold, installed, and supported through a network of specialized distributors across North America. Check the where to buy page to find the distributor in your area.

STILL HAVE QUESTIONS?

Visit our FAQ page to see a full list of the most frequently asked questions or get in touch with us by submitting an inquiry through our contact us page.