What is a DPF system?

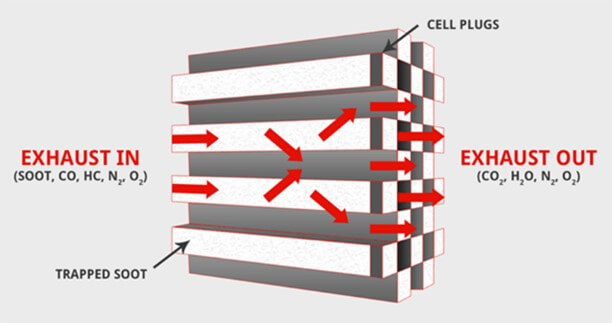

DPF stands for Diesel Particulate Filter. The DPF system is a filtration system designed to trap soot and prevent it from exiting the tailpipe and entering the atmosphere from a diesel engine. Exhaust Gas Recirculation (EGR) systems have been integrated into modern diesel engines to help reduce harmful NOx emissions. A result of incorporating these systems is that it tends to reduce exhaust temperatures. This reduction in temperatures in the combustion chamber and the exhaust stream led to a large increase in unburnt soot exiting the tailpipe. The DPF system was designed to keep that soot from entering the atmosphere.

How does the DPF system trap soot that is accumulated?

DPF filters are typically made of a ceramic honeycomb-style substrate that can filter out tiny soot particles without creating a large restriction in the overall exhaust flow. These are made primarily of silicon carbide or cordierite. The filter will trap soot particles as the gases are force to flow through the filter walls leaving all solid particulate matter behind. Once the filter reaches capacity and the restriction level becomes too high, the filter goes through a process called regeneration. This will be covered in more depth shortly.

What parts are in the DPF system?

DPF systems will have a few parts in common in nearly all heavy-duty trucks after MY 2010. These main components are:

- DPF filter (Diesel Particulate Filter)

- Diesel oxidation catalyst (DOC) filter

- Hydrocarbon Doser (7th injector)

- DPF pressure differential sensor

- Multiple exhaust gas temperature sensors

- SCR chamber

- DEF Doser

- EGR system

- Turbocharger

All these components are engineered by the manufacturer to work together so the DPF system will operate as intended.

How does a DPF regeneration work?

DPF Regeneration refers to the cleaning and clearing of the collected particulate matter from the DPF. Regeneration prevents the soot from clogging the filter. And to clear the material, the DPF burns them via the heat of the exhaust (passive regeneration) or via extra fuel injected into the device (active regeneration). Over time you are likely not only to experience active and passive regeneration, but also forced regeneration.

Passive Regeneration

Passive regeneration refers to the automatic process that takes place in the exhaust system/DPF during normal vehicle operation when exhaust gas temperatures reach between 3500C-5000C (5720 F-9720 F) for sustained periods of time. The temperature at which passive regeneration begins to occur is dependent upon the types and blending percentages of the precious metal coating on the DPF substrate.

Active Regeneration

Active regeneration is a process in which extra fuel is injected into the exhaust stream ahead of the DOC, so that its temperature can be raised to burn off the excess soot which is starting to block your DPF. Active regeneration is particularly useful for those vehicles that tend not to drive long distances at high speeds (i.e. vocational, P&D, construction, drayage, etc.). Your truck may struggle to burn off the excess soot without active regeneration if it isn’t in use long enough, at high enough engine speed to complete the regeneration cycle. Your electronic control unit (ECU) will recognize when this process is needed and instigate it accordingly.

Forced or Parked Regeneration

This occurs when the control module senses that the back pressure has increased to the point that it recognizes that it has reached its capacity. The check engine light will illuminate on the vehicle dashboard, typically after an extended period of idling. This type of regeneration occurs only when the vehicle is stationary, and it requires action on the part of the vehicle operator. The vehicle operator must set the park brake and enable the parked regeneration to begin. Engine rpm increases and raw fuel is injected into the exhaust gas at the exit of the engine to generate the appropriate regeneration temperatures. The stationary vehicle manual regeneration processes take about 30-45 minutes.

Whichever process is initiated, temperatures in the DPF filter increase until it burns off any soot collected. During this process, the soot gets reduced to tiny ash particles. The ash remains trapped by the DPF filter, but these ash particles are so much smaller that it frees up the restriction and your exhaust flow is regained. While this is happening the DPF pressure differential sensor and exhaust gas temperature sensors are monitoring the process and reporting back the state of the DPF system to the engine or aftertreatment computer. If there is a failure, then you will get a Check Engine Light (CEL) or a regen light that will stay active. It’s important to know what causes a failure because this can lead to more downtime if the system is not working correctly.

How long will regeneration work between service intervals?

So now that we understand what the components are, how it traps soot, and how the regen process works, you may ask, where does the ash go? The ash remains trapped in the DPF filter and will eventually reach a critical point where service will be necessary. How long it takes to reach this point will vary heavily and it mainly depends on what condition your engine is in, how well your EGR system functions, and what type of conditions you are operating in. For trucks running in local environments or with heavy idle time, they will require much more frequent service compared to a truck operated on mostly highways with nearly no idle time.

Other components within the system need maintenance on a more regular basis. In general, it is a good idea to have a yearly EGR tune-up done and replace your 7th injector (hydrocarbon doser) every 200-250k miles. It is also recommended that the DEF tank be flushed, DEF filler neck and the DEF filter be replaced every 150-200K miles.

A little maintenance within the DPF system will go a long way in preventing issues from coming up.